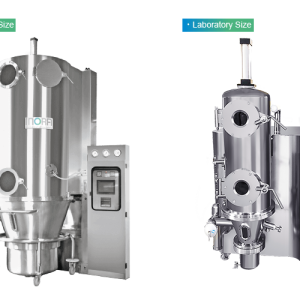

PRODUCTION-SCALE MILLING & SCREENING PLATFORM SDx™ SERIES – QUADRO

The SDx™ Series offers interchangeable milling and screening heads, including the U20x Comil® (conical milling), S20x FlexSift (security screening), and the D6Ax FitzMill™ (hammer milling). Each head can be easily and rapidly interchanged on a common drive base, thanks to SMARTdetect™ technology, which automatically recognizes the installed head and adjusts RPM accordingly. This feature significantly reduces setup time and eliminates the risk of human error.

SUITABLE APPLICATIONS INCLUDE:

- Oral Solid Dose (OSD) Pharmaceuticals

- Nutraceuticals

- Food Industry

- Chemical Manufacturing

- Cannabis Extraction Processes

- Active Pharmaceutical Ingredients (API)

FLEXIBLE MILLING AND SCREENING HEADS

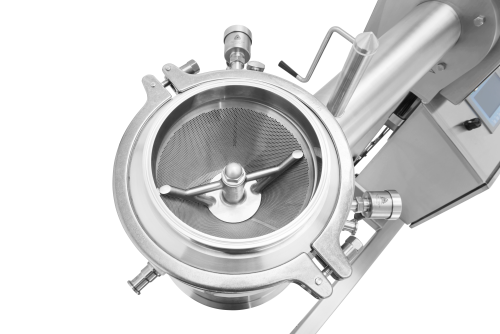

U20x Comil® – Conical Milling

U20x Comil® – Conical Milling

Benefits of U20x Comil® head:

- Delivers consistent and enhanced results compared to the Classic U20.

- Greaseless sanitary gearbox eliminates contamination risks and lowers operating temperatures, ensuring product integrity.

- Produces tighter and more uniform particle size distributions (PSDs), achieving 20–40% better target accuracy.

- Patented high-efficiency screen design provides up to 50% higher throughput and reduces product temperatures by up to 30%, depending on the material.

- Fully compatible with Classic U20 screens and impellers, allowing significant savings on tooling investment.

Key Features:

- Greaseless gearbox technology

- High-efficiency screen options

- Enhanced Clean-In-Place (CIP) capability

- Tooling compatibility with the Classic U20 range

- Scalable from SLS lab-scale through to SDx production-scale platforms

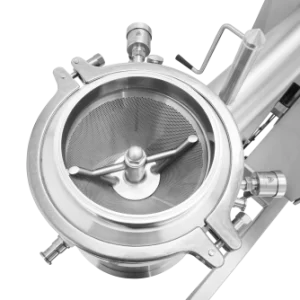

S10x FlexSift – Security Screening

Benefits:

- Efficiently replaces multiple traditional vibratory sifters with a single S10x unit, maintaining comparable throughput.

- Offers industry-leading capacity, delivering 40–50% greater throughput compared to similar centrifugal security screening technologies.

- Achieves optimal capacity range unmatched by competitive centrifugal security screeners.

- Features a greaseless gearbox design, completely eliminating contamination risks.

Highlights:

- Greaseless sanitary gearbox

- ATEX & XP hazardous-area certification available

- Scalable from laboratory (SLS Series) through pilot-scale to full production (SDx Series)

D6Ax FitzMill™ – Hammer Milling Technology

D6Ax FitzMill™ – Hammer Milling Technology

Benefits:

- Optimal solution for superior particle size reduction, especially for APIs, polymer-based hot melt extrusions, and oral solid dosage formulations.

- Achieves high efficiency with minimal product retention, ensuring excellent yield.

- Complete accessibility ensures quick cleaning and maintenance, minimizing downtime.

- Range of screens available to precisely meet desired PSD specifications.

- Includes optional cooling infeed for heat-sensitive applications.

Highlights:

- Simple, fast removal and assembly of milling head

- Complete (100%) surface accessibility for cleaning

- Hazardous-area compatibility (ATEX & XP certification)

- Fully scalable from lab-scale SLS models to SDx production platforms

SMARTdetect™ TECHNOLOGY ADVANTAGE

All SDx™ heads feature innovative SMARTdetect™ technology integrated into the control system, instantly identifying which head is installed and automatically adjusting the RPM settings, ensuring correct, safe, and optimal operation without manual intervention.