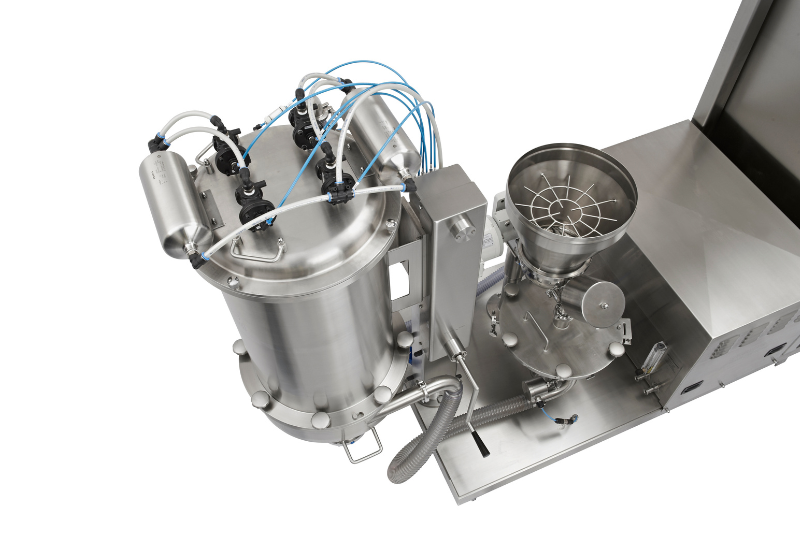

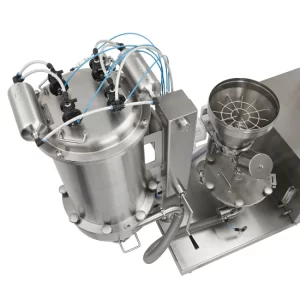

ULTRA FINE POWDER GRINDING F10 – QUADRO

The Quadro F10 Fine Grind Mill is an advanced, standalone ultra-fine powder milling system specifically designed to achieve optimum particle size reduction in a single pass. The mill delivers exceptional precision and consistency, particularly effective with challenging-to-grind materials such as APIs, excipients, fine chemicals, nutraceuticals, premium flavors, fragrances, and other high-value powders.

KEY ADVANTAGES:

KEY ADVANTAGES:

- Advanced ultra-fine grinding technology achieves target particle size (D50) in the range of 5–45 microns (<325 US mesh).

- Improves on-spec product yield by up to 40% compared to traditional fine milling technologies.

- Unique two-stage grinding technology produces exceptionally narrow and stable particle size distribution (PSD) curves.

- Compact, mobile design easily integrates with existing powder collection systems.

- Minimal heat generation, low energy consumption, and quiet operation.

- Quick cleaning and rapid batch turnover minimize downtime.

INDUSTRY APPLICATIONS:

- OSD Pharmaceuticals

- API Pharmaceuticals

- Nutraceuticals

- Food Processing

- Chemicals

- Cannabis Processing

TECHNICAL SPECIFICATIONS (Model F10):

- Motor Power: 7.5 kW

- Operating Speed (RPM): 3600 – 8400 rpm

- Throughput Capacity: 10 – 200 kg/hr

- Target Particle Size Range:

- D90 within 20 – 60 microns

- D50 within 5 – 45 microns

DETAILED DESIGN FEATURES:

- Standalone, fully automated integrated milling system, eliminating the need for ancillary equipment.

- Optimized design maximizes yield and profitability while minimizing product waste.

- Environmentally friendly with reduced noise, dust, and energy consumption.

BENEFITS OF CHOOSING F10 FINE GRIND MILL:

- Highest precision and uniformity in particle size distribution.

- Significant reduction in off-spec product waste.

- Enhanced productivity and reduced production cycle time.

- Compliant with stringent safety and quality standards (cGMP, ISO, ATEX).