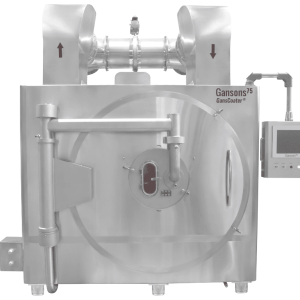

SatiCus proudly introduces the GansCoater automatic tablet coater– the world’s leading tablet coating solution, exclusively distributed by Gansons. With more than 1,200 installations, the GansCoater film coating machine has proven effective in ensuring a uniform, smooth coating, enhancing the quality and stability of pharmaceutical products. This product is trusted by the world’s leading manufacturers, meeting the most stringent standards of the pharmaceutical industry.

Milling and Mixing

Gansons High Shear Mixer Granulator (HSMG) is a high-performance mixing and granulation device designed to meet the stringent requirements of industries such as pharmaceuticals, food, and chemicals. With over 50 years of experience in manufacturing mixing equipment, Gansons has developed the HSMG with advanced features to optimize performance and comply with international standards.

Milling and Mixing

SuperGran® is a cutting-edge wet granulation technology designed to overcome challenges in traditional granulators, such as non-linear scalability, long processing times, inconsistent granulation, and high energy consumption. Equipped with 1 to 4 uniquely designed impeller blades connected to a rotary shaft and scraper, it creates a uniform shear environment for rapid, consistent, and scalable granulation. As a high-speed granulator, SuperGran® is widely used in the pharmaceutical, chemical, food, nutraceutical, and EV battery industries.

GansCoater® is an advanced film coating system that meets cGMP, FDA 21 CFR Part 11, CE, UL, ATEX, and ISO 9001 standards, ensuring quality, safety, and strict regulatory compliance. With the capability to handle batch sizes ranging from 50 to 300 g, the machine is equipped with an R-mini nozzle, Watson Marlow peristaltic pump, and a signature smooth, perforated coating pan. Its compact design, easy operation, and tool-free process unit changeover optimize coating speed, film uniformity, and minimize material loss.

Block "news" not found