Filling & Packaging Machine

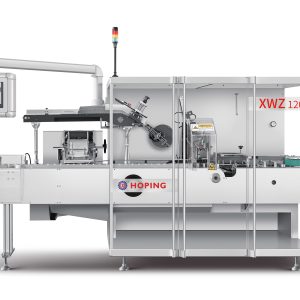

The Cartoner XWZ120 is an intermittent horizontal cartoning machine designed for industries such as food, cosmetics, chemicals, and other related sectors. It is highly adaptable, with short mold adjustment times, easy assembly, and debugging. The machine is suitable for both large-scale single-product production and small-batch multi-product manufacturing. It can also be integrated with various banding machines for efficient packaging.

Filling & Packaging Machine

Intelligent fully servo high speed blister line DHL8005H, a full servo blister line, which consists of a blister packaging machine and a cartoning machine. (Connected by D3 intelligent top-loading parallel robot). It can complete the switching of 1-5 boards for cartoning within a minute.

Filling & Packaging Machine

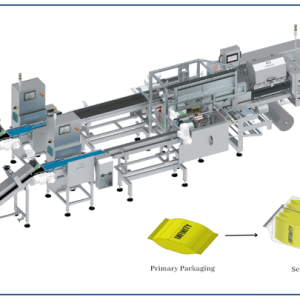

The secondary packaging machine for pouches from Infinity Solutions is a modern device designed to optimize the final packaging stage in production. With its ability to handle packages quickly and efficiently, this equipment helps businesses save time, increase productivity, and ensure that products are well-protected before reaching consumers.

Filling & Packaging Machine

XWK4060 stretch banding machine is a new generation of end-of-line packaging machine developed by us to meet the needs of our customers. Widely used in the food and pharmaceutical industry cartoning product combination bundling. The machine's electric control system adopts imported electrical components, and the main mechanism drive is pneumatic + servo motor, which has the characteristics of fast packaging speed, stable running, easy to change molds and simple operation. And it can be connected to a packaging line with Blister Machines, Cartoners, and Case Packers.

Filling & Packaging Machine

TubeFiller TF3000 is designed to reduce repetitive manual filling of any format laboratory racked tubes.Based on its dedicated function to fill "any tubes in any rack" the design includes a very stable filling arm with 2 side rails for best position recovery, precise XY position axes, an easy manual height adjustment, and an integrated pump to cover the standard microbiology filling range. No need for an additional pump for standard applications. Especially appreciated by our customers; under the tubes there is stainless steel only! Easy to clean, no rims or gaps and therefore Microbiology friendly and optimal for Food-, Pharma- or Cosmetic- Lab environments.

Filling & Packaging Machine

VACTRAC III – NON-CONTACT VACUUM AND PRESSURE INSPECTION SYSTEM – PECO INSPX

The VacTrac III is a robust and cost-effective system designed to verify vacuum or pressure levels in metal closures without contact. Utilizing a proven inductive, non-contact sensor, it delivers exceptional accuracy and reliability even in challenging environments where moisture may be present on the container lid. VacTrac III is built on a modern computing platform, offering an intuitive interface and powerful remote diagnostics capabilities. An optional advanced analytics package is available, providing valuable insights into inspection performance and overall production efficiency.

Filling & Packaging Machine

Solo is a high-speed, non-contact X-ray inspection system specifically designed for rigid containers such as metal cans, glass bottles, plastic jars, and cartons. Part of the ScanTrac Side View series, Solo uses side-view X-ray technology to detect foreign materials, package defects, and issues like knocked-down flanges or misaligned product positions. The system is installed directly over existing conveyor lines without requiring product transfer or contact, making integration seamless and cost-effective. With proprietary software, exceptional speed, and robust 24/7 remote support, Solo is the ideal solution for modern, high-volume production lines.