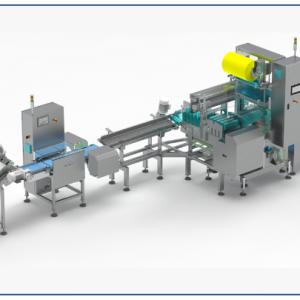

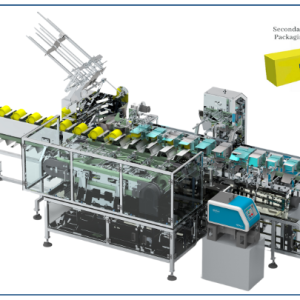

BLISTER MACHINE DPH320H II – HOPING

The DPH320H II is a full-servo blister machine based on the continuous drum sealing principle. It is widely used for pharmaceutical, food, cosmetic, and medical device packaging. This machine is compatible with various products, including tablets, capsules, ampoules, food items, and cosmetics.

It comes with two configuration options:

- Siemens motion controller with Siemens TP900 (9-inch) HMI screen

- Beckhoff motion controller with Beckhoff CP3915 HMI screen

Customers can select the appropriate configuration based on their specific production needs.

This high-speed blister machine is equipped with a special feeder for shaped pills and an edgeless punching system, significantly improving production efficiency. Additionally, it features high punching frequency, low energy consumption, precise and stable operations, and easy mold change.

FEATURES

✔ Max capacity: Up to 900 blisters/min (Standard plate size: 100×40 mm)

✔ Continuous roller sealing for high-speed and thorough sealing

✔ Different feeding methods available based on customer requirements

✔ Advanced motion controller & HMI screen

✔ Eyemark register system for accurate alignment

✔ 10-station full servo synchronous operation control

✔ Easy mold change system

✔ Splice station for smooth material change

✔ Stagger blister unstriped waste cutting, reducing material waste

✔ Designed to meet GMP standards

HIGHLIGHTS

Continuous Roller Sealing

- Ensures a small contact area and short heat time during sealing

- Provides thorough heat sealing and increased production speed

Servo-Controlled Punching Station

- Synchronizes blister operation with servo motor control

- Allows position shifting without changing gears

- Edgeless punching minimizes longitudinal waste to 1mm and eliminates transverse waste

Automatic Lubrication System

- The oil pump automatically refuels every 10 minutes (adjustable settings available)

- Enhances lubrication and cooling, ensuring smooth machine operation and prolonged lifespan

Packing Film Splicing Platform

- Simplifies the splicing process, ensuring smooth transitions

Double-Servo Structure & Lever Principle

- Enables compatible production for both alu-plastic (Alu-PVC) and alu-aluminum (Alu-Alu) blister packaging

Servo-Continuous Foil Eyemark Register System

- Uses independent servo rollers to pull out foil

- Corrects deflection before sealing, ensuring high-precision blister alignment

10-Station Full Servo Synchronization

- A single motion control system manages motion control, logic, and process control of all 10 independent stations

GMP-Compliant Design

- All medicine-contacting parts are made of stainless steel and non-toxic materials

Advanced Safety Features

- Emergency stop device

- Electronic counting system

- Batch number printing

- Automatic stop & alarm system for film depletion or breakage

- Smooth production flow with an intuitive process

Technical Data

| Project | Parameter |

| Max. Output | 180-900 blisters/min |

| Range of Stroke | 100-280 mm |

| Max. Forming Area | 320×280 mm |

| Max. Forming Depth | 12 mm |

| Motor Power | 3 kW |

| Power | 30.9 kW |

| Power Supply | 380V/50Hz |