Downflow Booths provide operator, process and / or product protection by utilizing HEPA filtered unidirectional laminar downflow to maintain an ISO Class 5 environment at rest within the work zone and capture particulates during open handling processes.

Applications:

- Pharmaceutical

- Cosmetics

- Nutraceutical

- Food

- Biological

- Animal

- Robotic

- Electronic

Features:

✔ Safe Change filter configurations are available for potent products,

selectable to change either internally or externally from the booth.

✔ Open loop or closed loop fan control configurations.

✔ Recirculating or single pass airflow configurations allowing use for

powder or solvent applications.

✔ Optional cooling coil systems to provide operator comfort.

✔ PVC strip curtains available

✔ Energy efficient EC fan units available to minimize operating costs.

✔ Optional hazardous area configurations to meet ATEX and NEC 505 requirements.

✔ Multiple control system options (HMI, Push Button or Sentinel Gold Microprocessor interfaces).

✔ Modular design allows future system adjustment without full booth replacement.

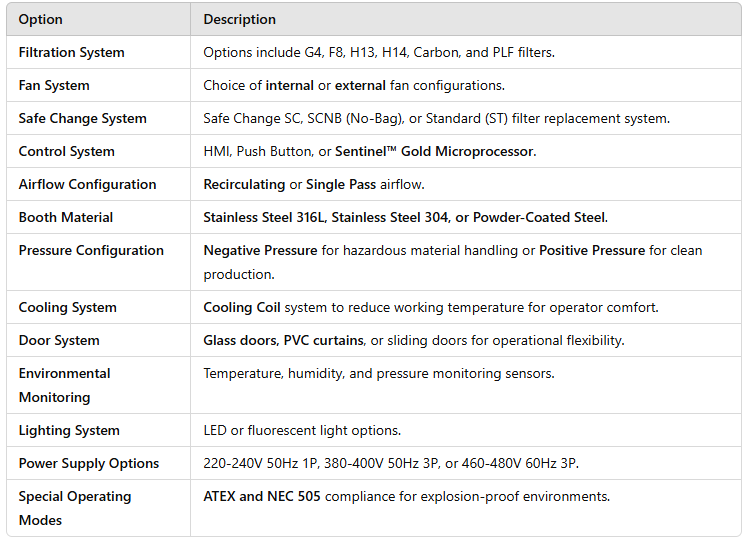

Configurations and options:

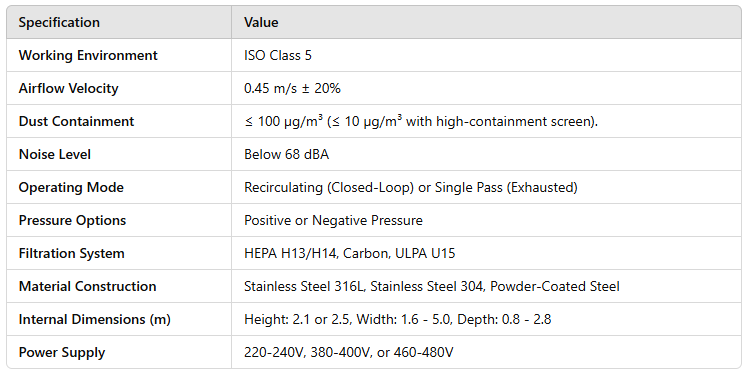

Specifications: