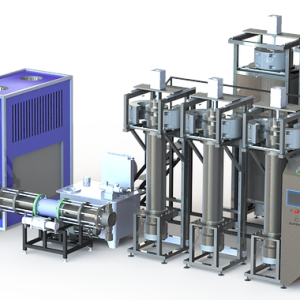

MODEL: SC-2000

SPECIFICATION

- 2 Liter extractor column,

- Extra 0.5 Liter extractor column

- Working pressure up to 345 Bar,

- Working temperature up to 70 °C

- With CO2 liquefaction system

- All surfaces in contact with food are stainless steel

- Smooth-honed reactor columns against microbial attachments

- Special design for aroma extraction from liquid sample

- Easy sample loading and cleaning process

- Three separators, two of which are pressure and temperature controlled

- Replaceable cyclone flow or bottom feeding apparatus in separators

- Trap solution, water, alcohol, etc. to the separators. can be added.

- Digital Automatic back pressure regulator (BPR)

- With CO2 recycling system

- Optional CO2 recovery feature

- Temperature control with PID algorithm

- Gas feeding or cyclone flow feature from the bottom to the separators