The VacTrac III is a robust and cost-effective system designed to verify vacuum or pressure levels in metal closures without contact. Utilizing a proven inductive, non-contact sensor, it delivers exceptional accuracy and reliability even in challenging environments where moisture may be present on the container lid.

VacTrac III is built on a modern computing platform, offering an intuitive interface and powerful remote diagnostics capabilities. An optional advanced analytics package is available, providing valuable insights into inspection performance and overall production efficiency.

Key Features

- 24/7 Remote Support: Integrated wireless connectivity enables global remote assistance. Over 95% of issues can be resolved remotely using Peco InspX’s powerful diagnostics platform.

- Robust IT Security: Full end-to-end IT security, with optional IoT module for seamless SCADA integration.

- No Container Spacing Required: The system inspects containers placed directly next to each other.

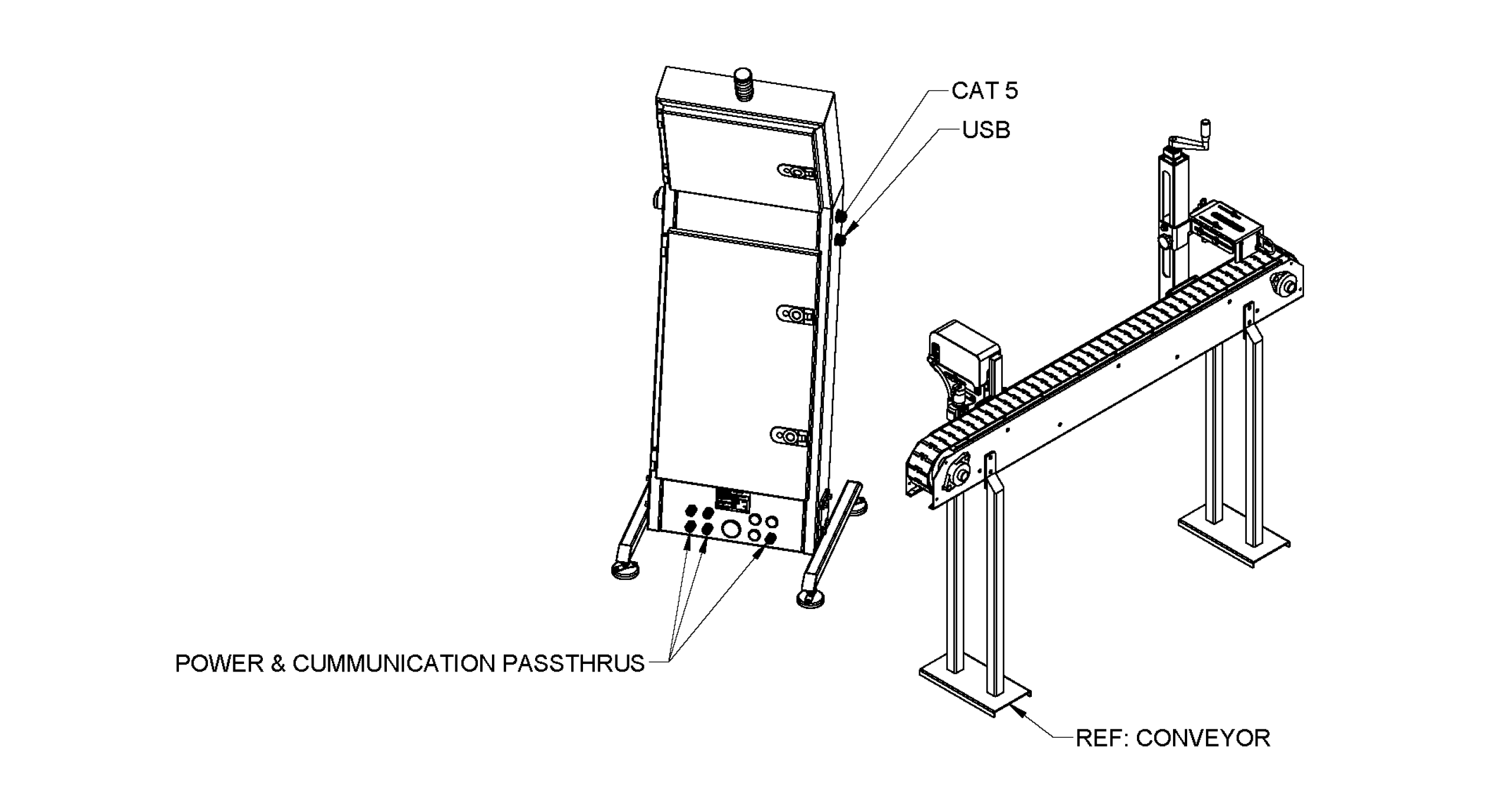

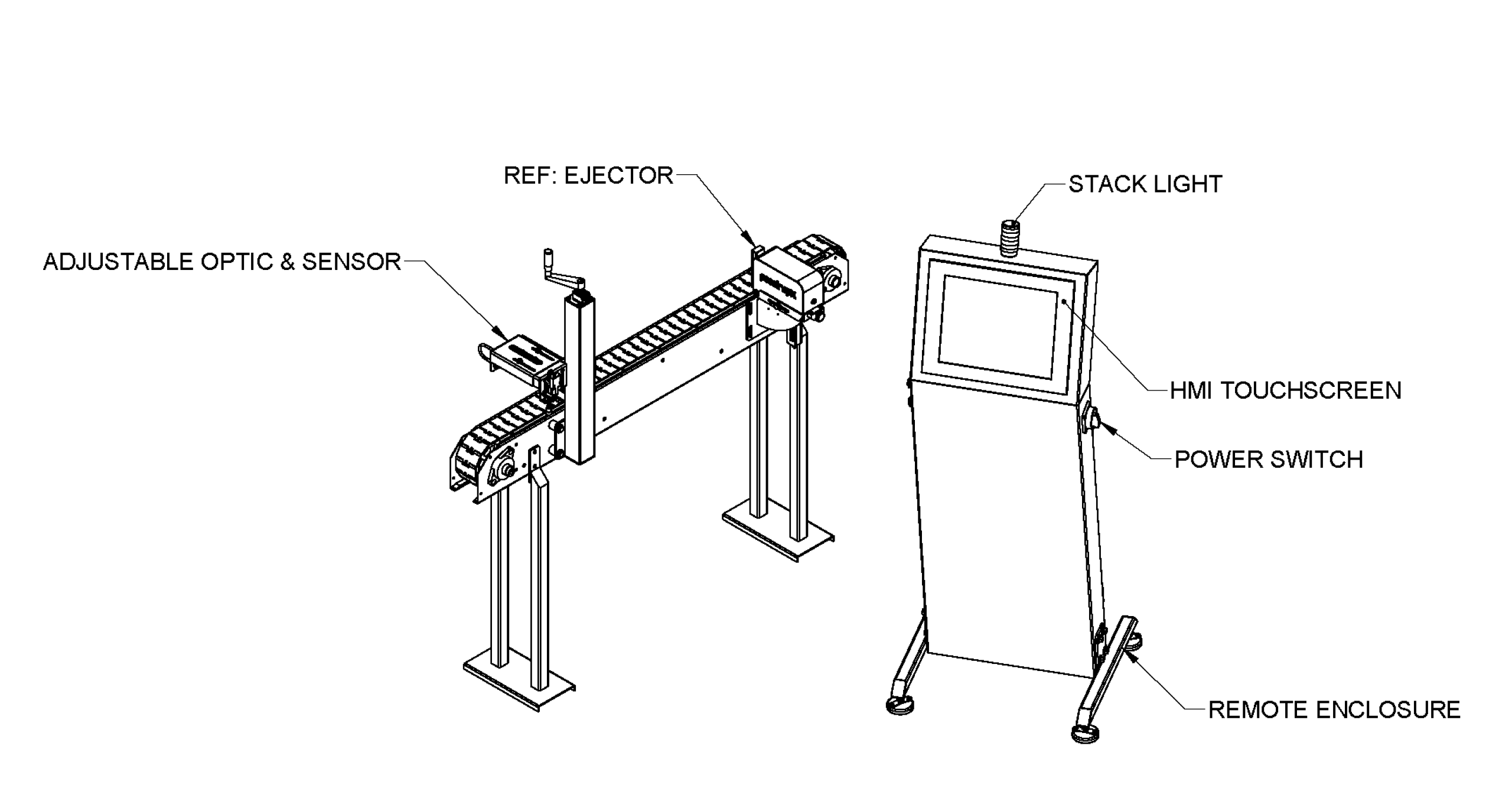

- Non-Contact, Over-Conveyor Installation: Mounts above existing conveyors without product contact or conveyor transfers, reducing jam risk.

- Vacuum Inspection for Metal Lids: Multiple algorithms assess lid deflection for accurate vacuum detection in metal can closures.

- Pressure Inspection for Pull-Tab Cans: Advanced software compensates for tab positioning during pressure evaluation.

- Tamper-Evident Band Detection: Compatible with external sensors to verify the presence of tamper-evident bands on closures.

Typical Applications

- Seamed metal cans

- Ring-pull containers

- Plastic and glass bottles with metal closures

Technical Specifications

- Sensor Architecture: Analog inductive non-contact

- Installation: No internal conveyor – mounts over customer’s conveyor

- Aperture Size: Unlimited height; 6.0” (152.4mm) standard width

- Available sensor sizes: 18, 25, 36, 42 mm

- Environmental Rating: IP65 standard; optional washdown/corrosion-resistant design

- Line Speed: Up to 2,000 containers per minute

- Input Power: 120 or 240 VAC

- Compressed Air: 80 psi @ 5 cfm (for ejection only)

- Operating Temperature: 33°F – 113°F (1°C – 45°C)

- Deflection Accuracy: ±0.005 inches

- System Dimensions (LxDxH): 9 x 30 x 47 in (229 x 762 x 1,194 mm)

- Safety Rating: Redundant – Category 4, Performance Level E

- Industrial Computer: Linux Embedded OS

- Connectivity: Integrated WiFi, Ethernet, or Cellular

- SCADA Integration: Programmable digital outputs available

- Operator Interface: 17” touchscreen

- Construction: Standard 304 stainless steel; optional 316L/passivated finish

Optional Features

- Cocked/Missing Cap Detection: Inexpensive sensor ensures caps are properly applied

- Remote Operator Console: Enables full monitoring and control up to 6 meters away

- Sanitary Design: IP69K-rated enclosure for high-pressure washdown environments

- Foil Seal Detection: Verifies presence of foil seals under caps

- Reject Management Package:

- Lockable reject bin

- Positive reject confirmation sensors

- Full-bin alert sensor

- Air pressure monitoring

- Optional software-controlled access lock

- Ejection Options:

- Single/multiple solenoid

- Swing arm

- Lift gate

- Drop gate

- Air blast

- Flexible rail

- Guided path

- Heavy-duty configurations for large or heavy containers