🔧 Key Features

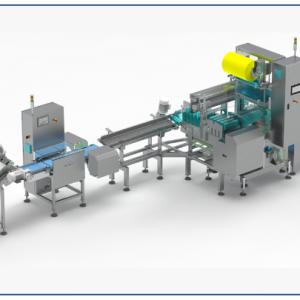

- Non-contact installation

Mounts directly over the customer’s existing conveyor — no product handling required. - Ultra-high throughput

Capable of inspecting up to 2,000 containers per minute (700 ft/min), supporting high-speed lines. - Modular, low-maintenance design

All components are modular for easy replacement, minimizing downtime. - Advanced inspection software

Detects a wide range of foreign materials and container-related defects using proprietary algorithms. - 24/7 remote diagnostics

Integrated wireless connectivity allows real-time global support. Over 95% of issues are resolved remotely. - Certified radiation safety

Complies with major safety standards: 21 CFR 1020.40, CE, UL, CSA, and FDA guidelines.

🧪 Typical Applications

- Metal food or beverage cans

- Glass or plastic bottles

- Rigid cartons or plastic containers

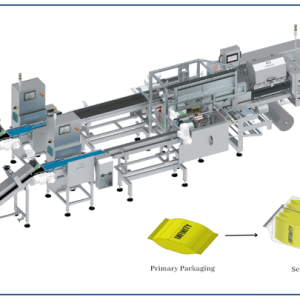

- Stand-up pouches and bags

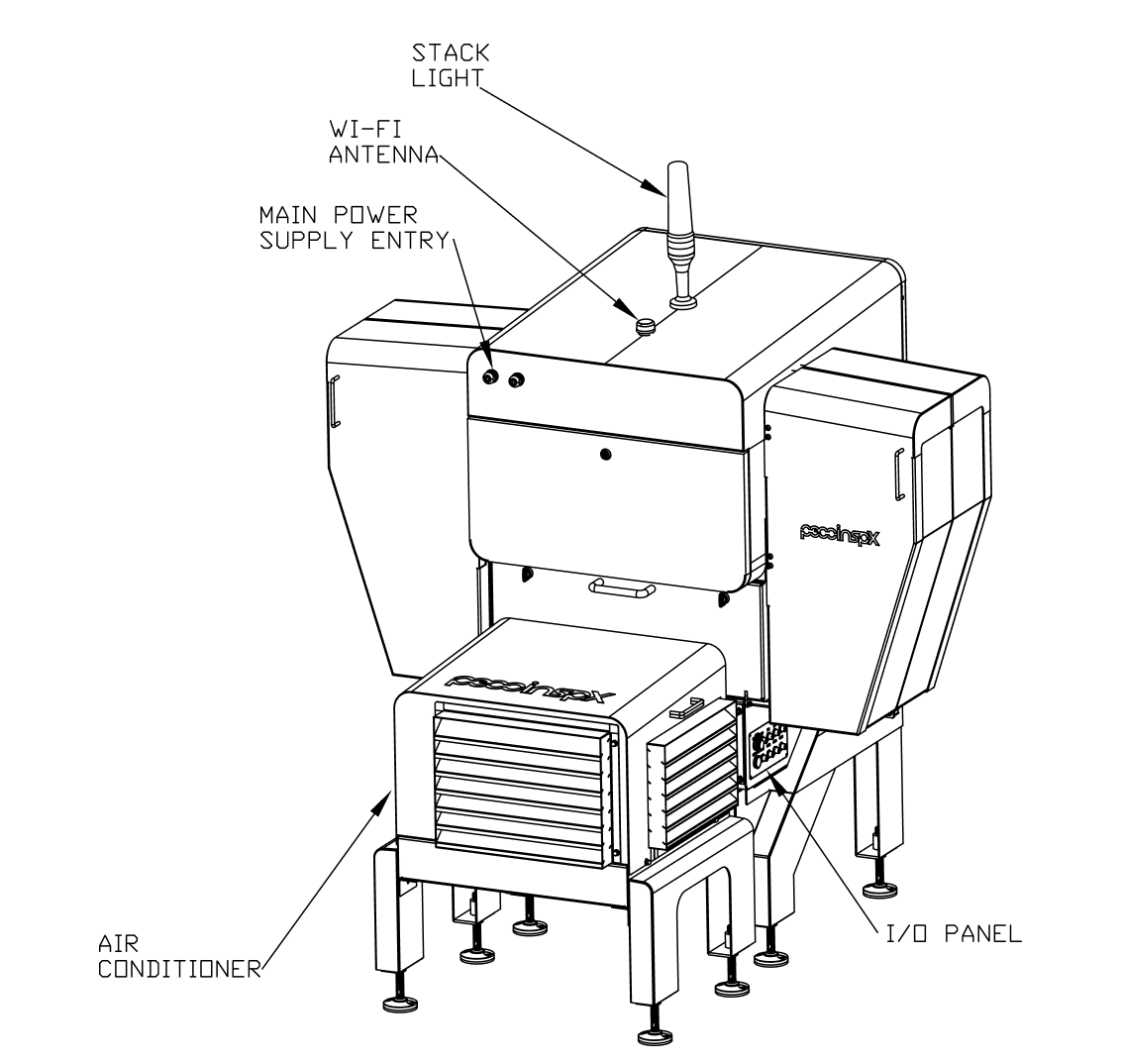

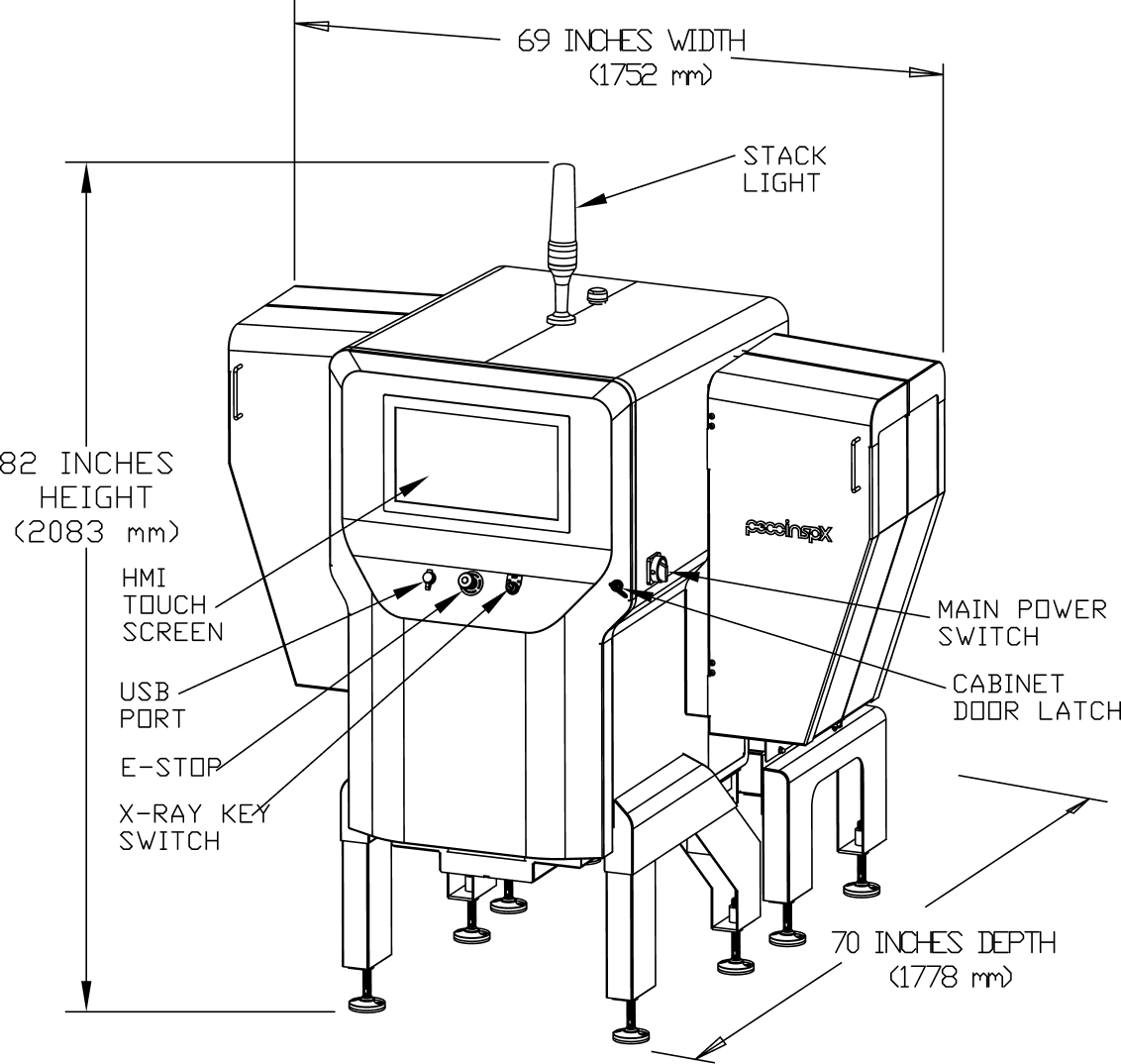

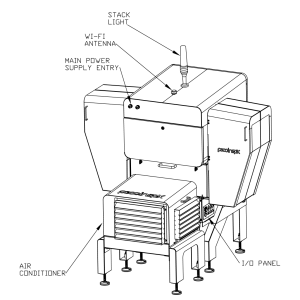

⚙️ Technical Specifications

| Category | Details |

| Inspection Technology | Side-view X-ray system |

| Installation | Mounts over existing conveyor – no internal conveyor |

| X-ray Tube Configuration | High-contrast single-beam X-ray with independent power supply |

| Diode Resolution Options | 0.8 mm, 0.4 mm, 0.2 mm (configurable) |

| Aperture Dimensions | Width: 229 mm (9”) Height: 300 mm (12”) |

| Line Speed | Up to 213 m/min (700 ft/min), ~2,000 containers/min |

| Power Supply | 120 or 240 VAC |

| Air Supply | 80 psi @ 5 cfm (for reject system only) |

| Environmental Rating | IP66 standard; optional IP69K or passivation |

| Operating Temperature | 1°C to 45°C (33°F to 113°F) |

| System Dimensions (LxWxH) | 1,727 x 1,092 x 1,840 mm (68 x 43 x 72 in) |

| Safety Rating | Category 4 – Performance Level E |

| Control Computer | Industrial PC – Windows 10 – SSD storage |

| Connectivity | WiFi, Ethernet, or Cellular |

| SCADA Integration | Compatible with Ignition, Wonderware, FactoryTalk, Kepware (OPC-UA) |

| Cloud Support | Azure IoT, AWS, Google Cloud via MQTT |

| Operator Interface | 20-inch touchscreen |

| Construction Material | Standard: Stainless Steel 304; Optional: 316L/passivated |

🧰 Optional Features

- Inspection Image Archiving

Optional storage of all X-ray inspection images with auto-classification of rejects. - Reject Management Package

Includes:- Lockable reject bin

- Reject verification sensor

- Full bin alert sensor

- Air pressure monitoring

- Software-controlled access lock

- Ejection System Options

Multiple rejector types available:- Single/multi-solenoid

- Swing arm

- Pusher

- Lift gate / drop gate

- Air blast

- Flexible rail

- Guided path

- Heavy-duty ejectors

- RFID Access Control

Enables secure operator authentication using standard ID badge protocols. - Remote Operator Console

Allows full monitoring and control up to 6 meters away. - Cap Inspection Support

Optional sensors for detecting tilted or missing caps. - Foil Seal Detection

Verifies presence of foil under caps (for containers with induction sealing). - Sanitary Design

Optional IP69K-rated enclosure for high-pressure washdown environments.