Conductivity detection is ideally suited to inorganic reduction/oxidation reaction, proton exchange, metal ligand binding and micelle formation from surfactants. Conductivity can bring complementary information to absorbance meaning the simultaneous acquisition of two signals is possible.

UHT System

Accurately combining ingredients is a crucial step in formulating and scaling up the production of new products. Improper mixing can lead to clumping and fat separation. The ability to mix powders and liquids evenly is essential for ensuring product quality, safety, and shelf life. With the emulsifier MPV231EF, this cost-effective and time-saving system makes it easy to create stable emulsions with the finest droplet sizes possible. Its high level of automation ensures a reliable mixing process and consistently reproducible trial results. With a unique capacity of just 20L per batch and the flexibility of this mixing equipment, it becomes an invaluable machine for any application laboratory or R&D center.

Air Filtration Systems

The explosion proof industrial vacuum cleaner MTL 202 BL - ATEX industrial vacuum cleaner is specially designed to meet the dust extraction needs in hazardous industrial environments with the ATEX Zone 22 explosion-proof certification. This vacuum cleaner is ideal for industries that require high safety standards, including food, cement, ceramics, and electronics.

Filling & Packaging Machine

The FillTrac is a high-performance, non-contact X-ray fill level inspection system used to accurately measure liquid or solid fill levels in sealed containers such as bottles, cans, and cartons without opening or interrupting the production line. Developed by Peco InspX, a U.S.-based leader in inspection technology with over 40 years of industry experience, FillTrac combines precision, durability, and ease of use in a compact and environmentally sound design.

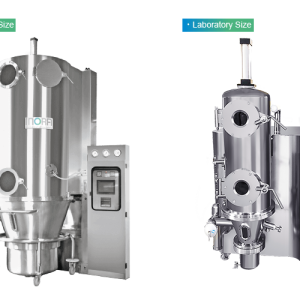

The fluidized bed granulator dryer is a multifunctional device that integrates three processes: mixing, granulating, and drying, all in one machine, delivering outstanding efficiency and time savings. Using the principle of hot and purified air to create a uniform fluidized flow, the machine ensures drying speeds 10-20 times faster than traditional methods while maintaining the granules' quality with precise and consistent moisture content.

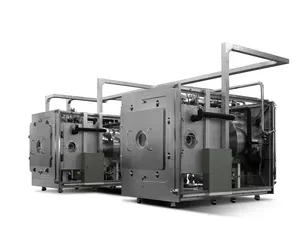

The pharmaceutical freeze dryer system is a modern solution ensuring precise control over the lyophilization process, meeting bGMP/cGMP standards. Equipped with an advanced vacuum system, automatic control, and SCADA data monitoring, it delivers high efficiency and maximum reliability for the pharmaceutical and biotech industries.

The freeze dryer of the FD/FDS/MCFD/TFD series is an ideal device for small-scale laboratory research. Featuring an advanced automatic cooling system, the machine ensures the condenser temperature drops below -80°C, effectively collecting moisture and preventing damage to the vacuum pump. Its flexible control modes, both automatic and manual, allow for optimal freeze-drying processes tailored to different sample types. Additionally, its compact design, ease of use, and simple maintenance make it a perfect choice for pharmaceutical, food technology, chemical, and biological applications. The machine is certified with ISO9001, ISO14001, and CE, ensuring high quality and reliability.

The Lyoph-Pride 03 tabletop freeze dryer is an advanced device designed to meet the needs of small-scale laboratory research. With a temperature control system ranging from -45°C to +60°C, a condenser reaching -70°C, and hot gas defrosting technology, the machine ensures optimal freeze-drying performance. The LCD touch panel allows for easy operation, while the automatic monitoring system ensures high precision.