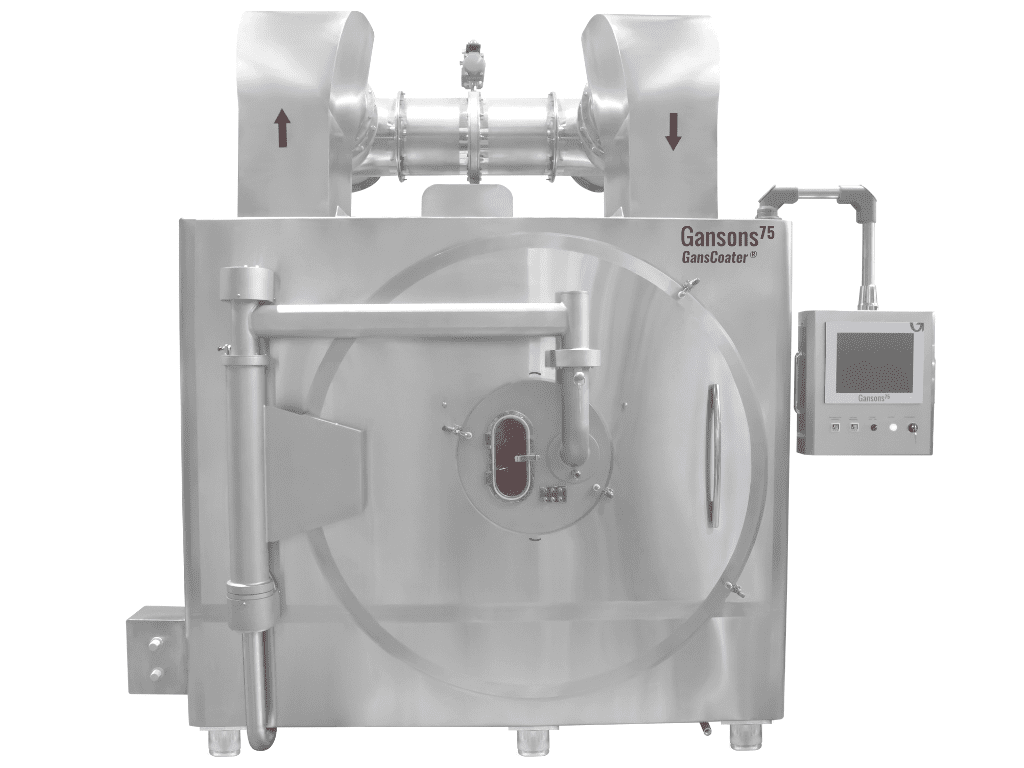

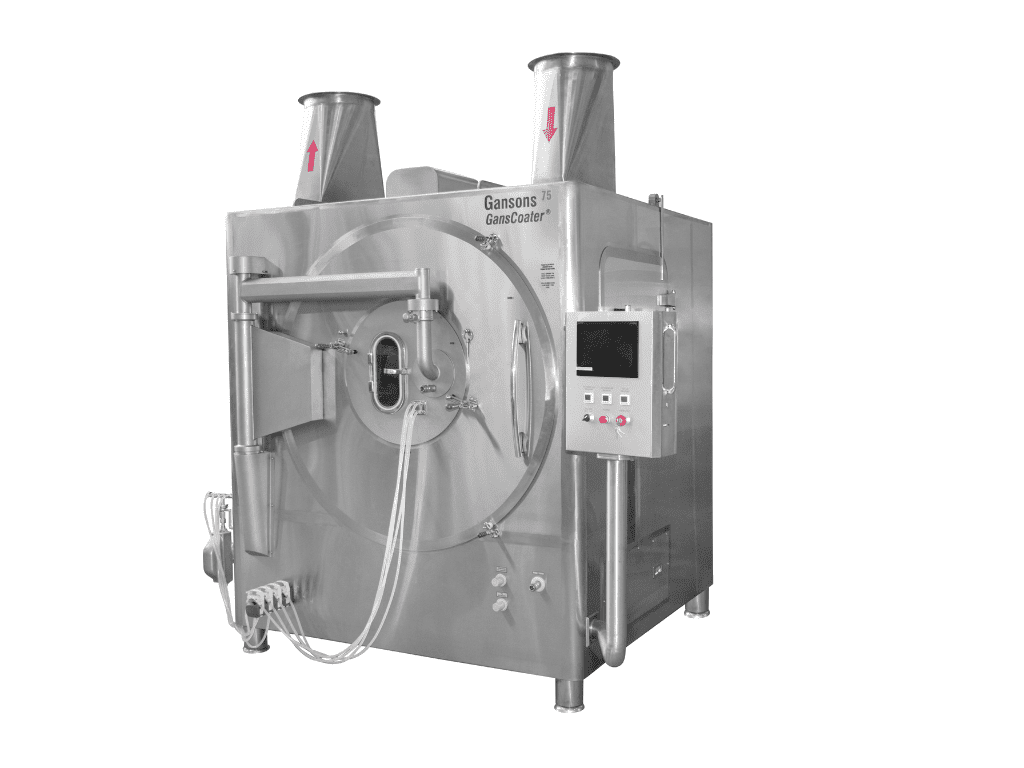

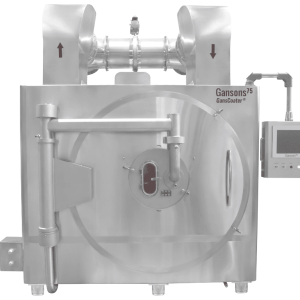

MODEL: THE GANSCOATER

Outstanding features

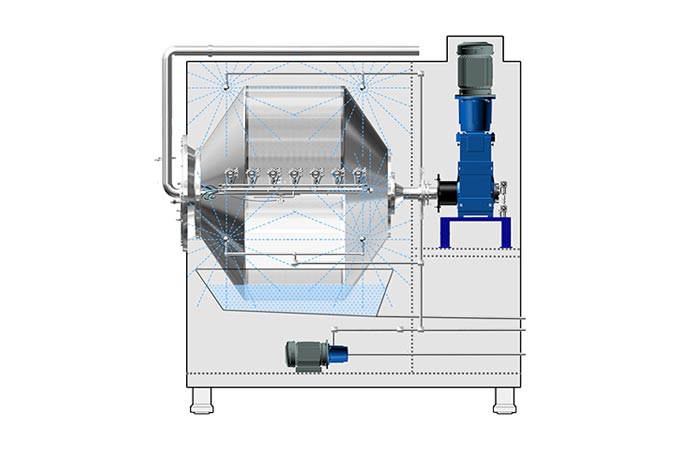

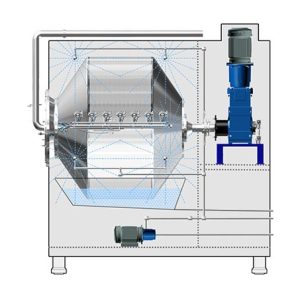

- AeroFlo™ shield (patented):

- Increases drying efficiency thanks to the perforated design.

- Reduces solution splashing.

- Eliminates dead zones, and increases mixing efficiency.

- Prevents tablet wear.

- Coating drum:

- The perforated design increases drying efficiency and makes cleaning and inspection easy.

- Super smooth surface reduces friction, limits tablet wear, and improves coating performance.

- Safe design, no sharp edges, avoids injury to operators.

- Easy access to the drum, making cleaning and maintenance convenient.

- Easy to observe and check product condition.

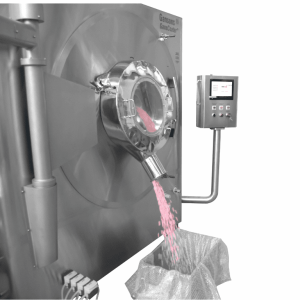

- The coating process uses GHPN III spray technology:

- GHPN III nozzles have superior performance compared to other types of nozzles, both when using water and organic solvents. GHPN III saves time, energy and raw materials, while providing high film coating efficiency.

- Modern electronic control:

- Electronic management system with remote monitoring and control capabilities, complying with cGMP standards

- Simple interface:

- Easy to use, and does not require users to have high professional knowledge.

- The product complies with good manufacturing practice (GMP) standards, ensuring hygiene and safety during the production process.

Technical specifications

| Features | Detailed Description | Benefits |

| GHPN III Nozzle | Anti-whisker design | Reduce the risk of clogging |

| No elastic contact parts | Easy maintenance, reduced costs | |

| 20% less compressed air consumption | Energy saving | |

| Wide, even spraying with uniform particle size | High-quality, uniform coating | |

| Film Drum | High smoothness (Ra < 0.1) | Defect-free coating |

| Large contact surface area | High drying efficiency | |

| Optimized shape | Fast, uniform coating | |

| Quick replacement (less than 5 minutes) | Flexible in production | |

| Large power reduction ratio | Flexible in production | |

| Simple, fast changeover | High productivity | |

| IR Sensor | Accurate measurement and control of tablet surface temperature | Ensure product quality |

| Measurement of temperature inside the coating | Effective coating process control | |

| Aerofoil Agitator | Enhanced mixing and drying | Efficient, even mixing |

| Better mixing and turning efficiency than other types of agitators | Uniform coating quality | |

| Smart Automation | PLC/SCADA control | Stable, reliable production process |

| Compliant with 21CFR11 standards | Ensure data quality | |

| IoT integration | Effective production management | |

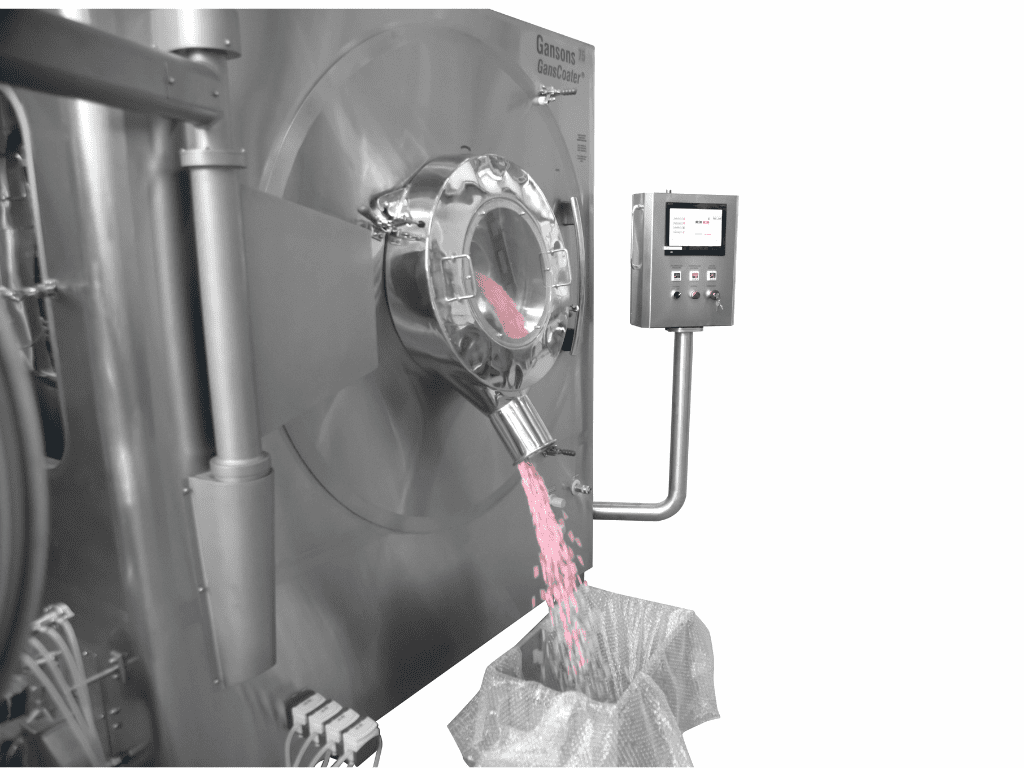

| Other Features | Automatic tablet loading and unloading | Increase productivity |

| WIP system | Easy cleaning | |

| Compatible with high-level cleanrooms | Ensure production hygiene | |

| Metering pump | Ensure raw material accuracy |

Application

Widely used in pharmaceutical production, especially for tablets and capsules, ensuring the quality and uniformity of coating according to international standards.