Applications:

✔ Laboratory containment for handling biological agents of up to level 4

✔ Virus and vaccine production

✔ Cell Processing

✔ Research and development

Features:

✨ Fully welded stainless steel 316L internal chambers with stainless steel 304 external housing.

✨ Exhaust air is double-filtered through high-quality ULPA filters (per IEST-RP-CC-001.3) with typical efficiency of >99.999% for 0.1-to-0.3-micron particles, better than HEPA filters.

✨ An integrated pass-through with interlocking doors permits materials transfer without risk of contamination.

✨ Single-piece, leak-tested glove assemblies which guarantee maximum protection.

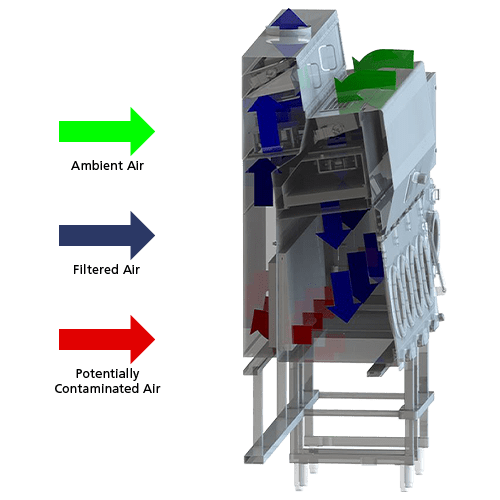

Principle:

Ambient air enters through the top inlet prefilter and is drawn by a fan, creating positive pressure that pushes clean air downward. A HEPA (H14) filter ensures ISO Class 5 air quality, keeping the main chamber and pass-through contaminant-free.

Around 90% of the air is recirculated, passing through the HEPA filter again, while 10% is exhausted to prevent heat buildup. In a Total Exhaust/Single-Pass Model, all air is expelled, ensuring continuous fresh airflow. This recirculation system extends filter life and reduces contamination risks.

Standard compliance:

• BS EN 12469

• Air Quality: ISO Class 5 (BS EN ISO 14644-1) and EC GMP Grade A

• H14 filters: HEPA as per EN 1822 and ULPA as per IEST-RP-CC001.3

Specifications: