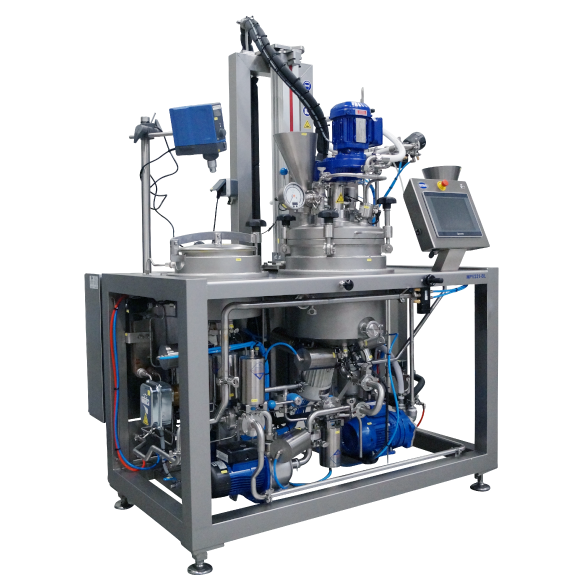

MODEL: MPV231EF

FEATURES

- Dosing, heating/cooling and mixing is HMI controlled

- Automatic & precise dosing of powders & ingredients

- under vacuum

- Cleaning-in-Place / CIP-program built-in

- Stainless-steel industrial design

- Easy integration into the production line

- Highly flexible configuration

APPLICATIONS

- Recombined milk

- Plant-based drinks

- Ice cream pre-mix

- Yogurt-based applications

- Sauces

- Personal care products

SPECIFICATION

Capacity

Blending tank size(s)

30 liter (product 20 liter net)

Oil tank size

10 L

Heating temp. tank (optional)

Up to 160°C [320°F]

Heating temp. oil tank

Up to 95°C [203°F], optional up to 160°C [320°F]

Overall dimensions

Dimensions LxDxH

1590 x 1180 x 2070 mm [62.60 x 46.46 x 81.50’’]

Weight

485kg [1069.3lbs] (depending on final configuration)

Required Utilities

Electrical supply

400Vac /3ph+N+E /50Hz/ 16A or 200-240Vac /3ph+E /60Hz/ 32A

Soft water

2-4 bar [29-58psi], 800L/h

Water supply

2-4 bar [29-58psi] , max. 240L/h

Air supply

7-9 bar [102-130psi]

Coolant (glycol / water)

2-4 bar [29-58psi], 300L/h

Drains

Required

STANDARD

Product tank – with

- Double jacket

- 2 Ingredients funnels

- Vacuum system

- High-shear mixer

- Anchor mixer with scrapers

Second (oil) tank

- Double jacket

- Automatic feeding of the product tank