MODEL: SuperGran®

Revolutionary Granulation Performance

• Decreases granulation time – experimentally proven to reduce process time by up to 90%*

• Produces uniform sized granules with controlled granule growth

• Mitigates dead-zones and product losses

• Linear scalability – up to 3,500 litres

• Sharp end-point detection based on time and other variables

• Eliminates bimodal behavior characteristic to drugs like paracetamol

• Easy cleaning

Intelligent Automation

• 21-CFR part 11 compliance for data integrity and storage, ALCOA+ compliant

• Responsive, ergonomic and intuitive interface

• 3 modes with multi-level password access

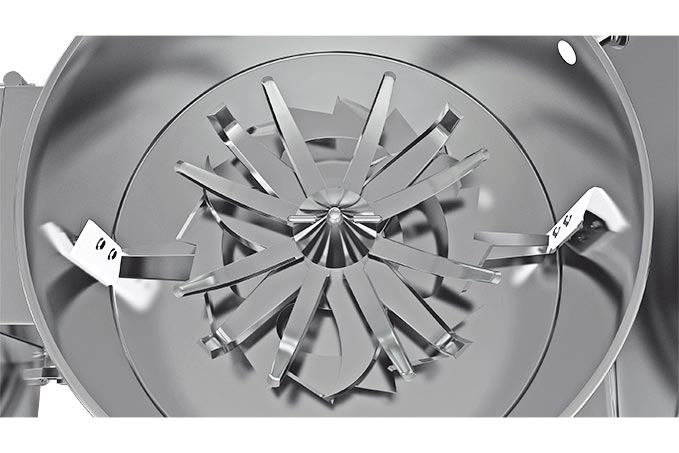

Blades

SuperGran® contains a combination of 1 to 4 impeller blades, each with a unique profile designed to provide an optimal outcome.

The combination of impeller blades depends on the product and desired output of the granulation process. The Upward blade is used for vortex mixing, 4-C blade is used for uniform mixing, S blade functions as a chopper, dissolver blades are used in the battery industry for slurry preparation etc.

Jacketed Process Bowl

SuperGran® can also heat/cool the substrate in-process

Scraper

The co-axial scraper attached at the bottom of the moving shaft prevents sticking of material to the inner wall and brings the material from the periphery into the shear zone. The scraper recirculates the material attached to the bowl and aids the complete discharge of material.

COMPLIED TO:

- cGMP

- FDA 21 CFR Part 11

- CE, UL, ATEX

- ISO 9001