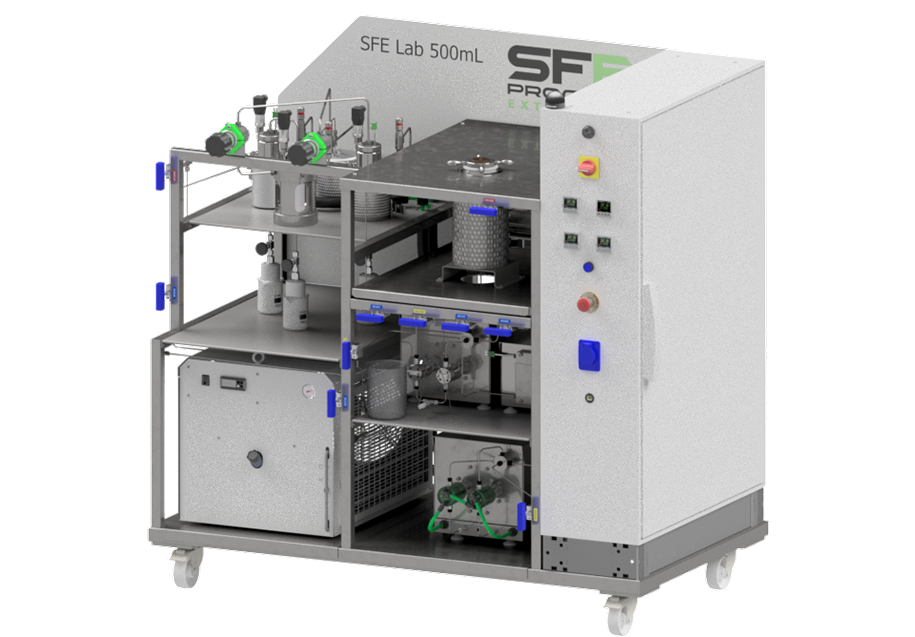

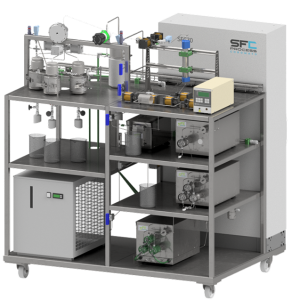

MODEL: SFE LAB

SPECIFICATION

| SFE LAB 100 ML | SFE LAB 500 ML | SFE LAB 1+ | SFE LAB 2+ | |

| Loading Capacity | 100 mL | 500 mL | 1 L | 2 L |

| Extraction Volume | 180 mL | 660 mL | 1.6 L | 2.7 L |

| CO₂ Flow Rate | 0-70 g/min | 0-70 g/min | 100 g/min | 0-70 g/min |

| Maximum Pressure | 1000 bar | 1000 bar | 1000 bar | 1000 bar |

| Maximum Temperature | 100°C | 100°C | 100°C | 100°C |

| Separation Capacity | 300 mL | 300 mL | 300 mL | 300 mL |

| Maximum Separation Pressure | 250 bar | 250 bar | 200 bar | 250 bar |

| Maximum Separation Temperature | 100°C | 100°C | 100°C | 100°C |