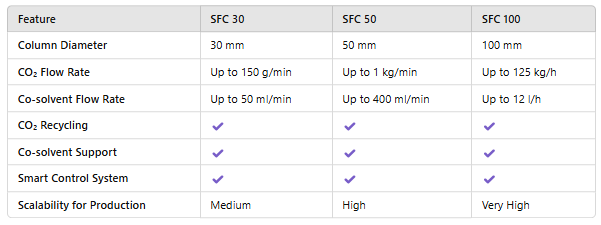

Supercritical Fluid Chromatography (SFC) systems, such as the SFC 30, SFC 50, and SFC 100 from SFC Process, offer several standout features that optimize the extraction and purification processes:

1. High Extraction Efficiency

- Utilizes supercritical CO₂ to enhance the solubility of compounds compared to HPLC.

- Delivers higher extraction efficiency with improved chromatographic resolution, especially for non-polar or chiral (optical isomer) compounds.

- Enables faster purification and separation while maintaining high quality.

2. CO₂ Recycling for Cost Savings

- The system can recover and reuse CO₂, reducing waste and lowering operating costs.

- A low CO₂ loss rate (~10%) minimizes environmental impact compared to traditional purification methods.

3. Co-solvent Support for Polarity Adjustment

- Can incorporate co-solvents (methanol, ethanol, acetonitrile) to expand the solubility range of CO₂, facilitating the purification of a variety of compounds.

- Allows for the adjustment of co-solvent ratios to optimize extraction performance.

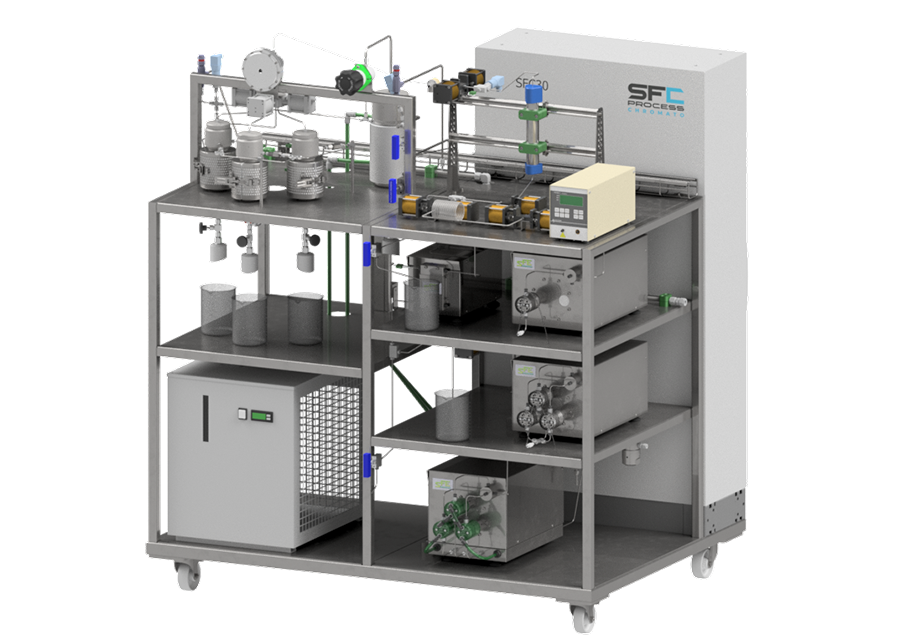

4. Flexible and Customizable Design

- Available with various chromatographic column sizes (30 mm, 50 mm, 100 mm) to meet demands ranging from preparative scale to industrial production.

- The system can be scaled and customized according to customer requirements, fitting different manufacturing processes.

- Compact design saves space and is easy to install and integrate into production lines.

5. User-Friendly Control Interface

- Equipped with intuitive control software that allows operators to easily monitor and adjust chromatographic parameters.

- Integrated remote monitoring capabilities enable process control without direct intervention.

6. Continuous Operation for Optimized Performance

- Allows for the replacement of CO₂ containers without interrupting operation, enhancing production efficiency.

- Capable of 24/7 operation with high stability.

SFC Process offers three models of supercritical CO₂ purification systems—SFC 30, SFC 50, and SFC 100. The main differences among these models lie in the column size, CO₂ flow rate, and co-solvent flow rate, making them suitable for various applications ranging from preparative to industrial-scale production.

Specifications: