MODEL: Gansons inONERD

KEY INFORMATION

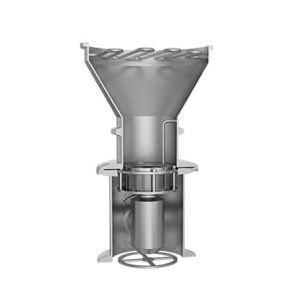

GansCoater®

Geared to handle lots of 50 to 300 g. Featuring the R-mini nozzle, the laboratory-scale of Gansons’ proprietary GHPN IIIRD nozzle, Watson Marlow peristaltic pump, Gansons proprietary baffles and signature smooth, perforated pan.

For wet granulation, the inONERD is equipped with Gansons High Shear Mixer Granulator of 0.5 L capacity. Our proprietary impeller design allows homogenous mixing and incorporation of binder for uniform granulation, that can be scaled up to pilot batches and beyond.

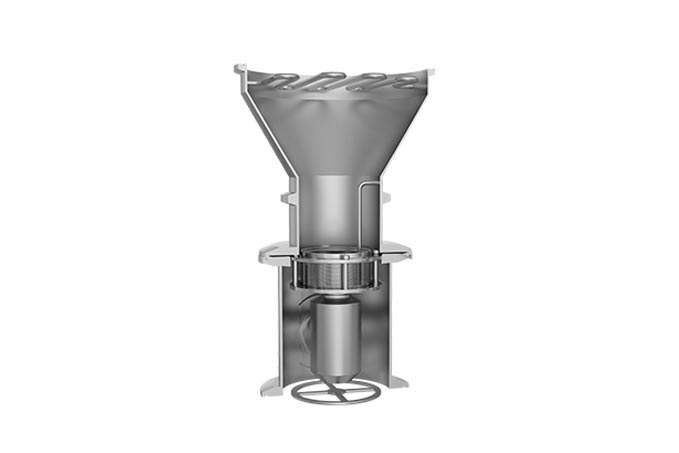

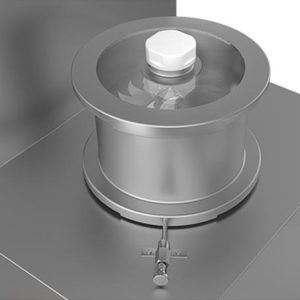

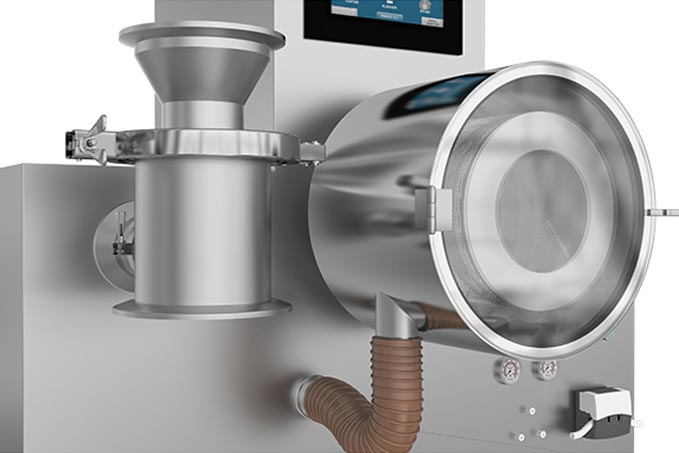

Gansons Fluidized Bed Dryer with Cyklon® Air Distribution System

The Gansons Fluid Bed Dryer comes powered with the global cutting edge in drying technology – Cyklon® Air Distributor System. The concentric rings with air-guiding channels on their underside provide a horizontal, spiral motion to the inlet drying air. The substrate is gently fluidized into a cyclonic pattern. This motion yields the following results:

• Drying at a fraction of the time compared to standard perforated air distributor plates: maximum drying efficiency

• Less inter-particle attrition means less granule breakage

• Push-pull system for controlled fluidization

• Uniform drying for sharper end point detection

COMPLIED TO:

- cGMP

- FDA 21 CFR Part 11

- CE, UL, ATEX

- ISO 9001