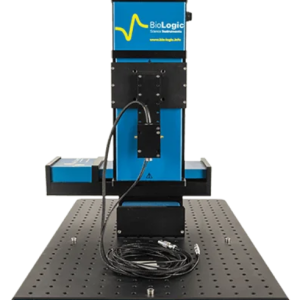

Movements are achieved by a precision servo motor controlled linear stage. Adjustable stroke length and accurate speed control are the exceptional features of this model along with its capability of achieving a uniform coating. This is a compact, bench-top coating unit having structural rigidity and is free from vibrations.

Model: HO-TH-01BC

FEATURES:

| Actuator | : | Servo motor |

| Drive mechanism | : | Lead screw |

| Speed control | : | Variable speed control |

| Stroke length max. | : | 400 mm |

| Drawing speed min | : | 2 micron / sec |

| Drawing speed max | : | 16 mm / sec |

| Load capacity | : | 5 Kg |

| Maximum substrate size | : | 1 foot x 1 foot x 3 mm |

| Number of containers | : | 3 |

| Container size | : | Compatible with 1 x 1 foot, 6 x 4 inch & 10 x 3 inch substrates |

| User interface | : | 20 x 4 line LCD & push buttons |

| Program memory | : | 5 Programs (Unlimited in PC mode) |

| PC connectivity | : | Serial port (RS 232) & USB |

| Software | : | Windows software |

| Power input | : | 230V / 50Hz |