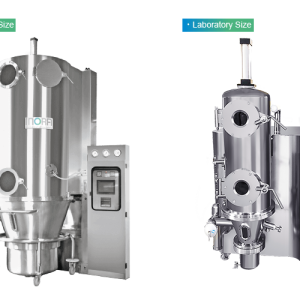

The fluidized bed granulator dryer is a multifunctional device that integrates three processes: mixing, granulating, and drying, all in one machine, delivering outstanding efficiency and time savings. Using the principle of hot and purified air to create a uniform fluidized flow, the machine ensures drying speeds 10-20 times faster than traditional methods while maintaining the granules' quality with precise and consistent moisture content.

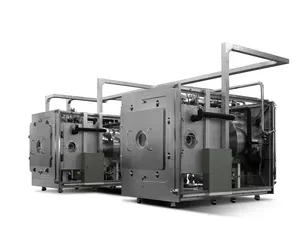

The pharmaceutical freeze dryer system is a modern solution ensuring precise control over the lyophilization process, meeting bGMP/cGMP standards. Equipped with an advanced vacuum system, automatic control, and SCADA data monitoring, it delivers high efficiency and maximum reliability for the pharmaceutical and biotech industries.

The freeze dryer of the FD/FDS/MCFD/TFD series is an ideal device for small-scale laboratory research. Featuring an advanced automatic cooling system, the machine ensures the condenser temperature drops below -80°C, effectively collecting moisture and preventing damage to the vacuum pump. Its flexible control modes, both automatic and manual, allow for optimal freeze-drying processes tailored to different sample types. Additionally, its compact design, ease of use, and simple maintenance make it a perfect choice for pharmaceutical, food technology, chemical, and biological applications. The machine is certified with ISO9001, ISO14001, and CE, ensuring high quality and reliability.

The Lyoph-Pride 03 tabletop freeze dryer is an advanced device designed to meet the needs of small-scale laboratory research. With a temperature control system ranging from -45°C to +60°C, a condenser reaching -70°C, and hot gas defrosting technology, the machine ensures optimal freeze-drying performance. The LCD touch panel allows for easy operation, while the automatic monitoring system ensures high precision.

The Table Top Freeze Dryer is an ideal device for small-scale laboratory research, offering flexible automatic and manual control options. Its advanced cooling system allows the condenser to reach temperatures below -80°C, ensuring an efficient freeze-drying process while preventing moisture from entering the vacuum pump. The device features fast cooling, a modern hot gas defrosting system, and precise vacuum control, optimizing sample preservation. With a compact design, user-friendly operation, and compliance with ISO 9001, ISO 14001, and CE standards, this freeze dryer is the perfect choice for pharmaceutical, biotechnology, food, and scientific research applications.

Laboratory Ovens are designed for precise temperature control, ideal for sample drying, sterilization, and testing at high-temperature conditions.

Dryer

Vacuum Ovens are designed to minimize drying time and protect heat-sensitive samples, providing higher efficiency than conventional ovens.