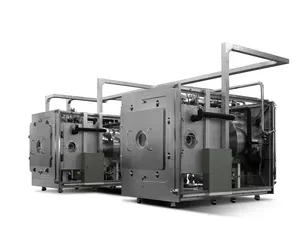

The pharmaceutical freeze dryer system is a modern solution ensuring precise control over the lyophilization process, meeting bGMP/cGMP standards. Equipped with an advanced vacuum system, automatic control, and SCADA data monitoring, it delivers high efficiency and maximum reliability for the pharmaceutical and biotech industries.

The Lyoph-Pride 03 tabletop freeze dryer is an advanced device designed to meet the needs of small-scale laboratory research. With a temperature control system ranging from -45°C to +60°C, a condenser reaching -70°C, and hot gas defrosting technology, the machine ensures optimal freeze-drying performance. The LCD touch panel allows for easy operation, while the automatic monitoring system ensures high precision.

The Table Top Freeze Dryer is an ideal device for small-scale laboratory research, offering flexible automatic and manual control options. Its advanced cooling system allows the condenser to reach temperatures below -80°C, ensuring an efficient freeze-drying process while preventing moisture from entering the vacuum pump. The device features fast cooling, a modern hot gas defrosting system, and precise vacuum control, optimizing sample preservation. With a compact design, user-friendly operation, and compliance with ISO 9001, ISO 14001, and CE standards, this freeze dryer is the perfect choice for pharmaceutical, biotechnology, food, and scientific research applications.

This supercritical drying system is designed to efficiently remove solvents, ensuring complete drying without altering the structure of the material. With automatic temperature and pressure control, the system operates with stability and precision. All surfaces in contact with food are made of stainless steel, preventing microbial attachment. Additionally, the system supports CO₂ recycling, optimizing performance and energy efficiency.