Extraction Systems

COUNTERFLOW SUPERCRITICAL CO2 EXTRACTION SYSTEM F-1000-SUPEREX

This supercritical CO₂ extraction system is designed for efficient extraction from liquid samples, with automatic pressure and temperature control, ensuring optimal performance and precision. All surfaces in contact with food are made of stainless steel, ensuring hygiene and preventing microbial attachment. The system also features an extra liquid feed pump, real-time flow rate display, and an easy sample loading mechanism, providing flexibility and safety in operation.

Extraction Systems

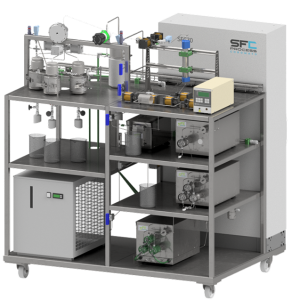

The SFE Lab 1+ is a cutting-edge supercritical CO₂ extraction system designed for laboratory-scale applications, offering precise control with a maximum pressure of 1000 bar and temperature up to 100°C. Its compact design, automated operation, and expandable capacity make it an ideal solution for efficient and versatile extraction processes in research and development.

Extraction Systems

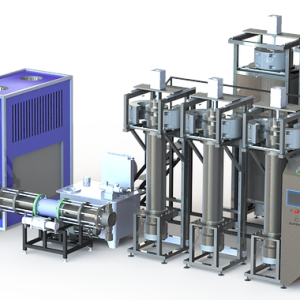

SUPERCRITICAL CO2 EXTRACTION SYSTEM IN PRODUCTION- SFE PROCESS

The supercritical CO₂ extraction system for industrial-scale production delivers high efficiency, enabling the extraction of pure compounds without altering their biological activity. With an automated design and optimized pressure and temperature, the system ensures fast, safe, and CO₂-efficient extraction. It is the ideal solution for the food, pharmaceutical, and cosmetics industries, enhancing product quality and optimizing production processes.

Extraction Systems

The Supercritical CO₂ Extraction System P-1000 offers an advanced solution for industrial production, enabling efficient and safe extraction of natural compounds. Designed with modern technology, the system operates automatically, optimizes energy use, and ensures high-quality extraction. Its precise temperature and pressure control technology allow for the processing of various raw materials, including those with high moisture content. This is an ideal choice for the pharmaceutical, food, and cosmetic industries, providing a clean and sustainable extraction process.

Extraction Systems

The Supercritical CO₂ Extraction System is an advanced solution for industrial production, utilizing supercritical CO₂ technology for efficient extraction of natural compounds. With a 100L extraction vessel, operating pressure up to 600 bar, and a maximum temperature of 90°C, this system ensures high efficiency and optimized extraction processes. Equipped with a Coriolis flow meter, precise PID controller, and automatic CO₂ recirculation system, it maximizes energy savings with up to 99% efficiency. Additionally, the optional separator cooling down to -10°C enhances compound fractionation capabilities. This is an ideal solution for pharmaceutical, food, and cosmetic industries, ensuring clean, safe, and sustainable extraction.

Extraction Systems

The Supercritical CO₂ Extraction System is designed for industrial production with 300L or 600L extraction vessels, a maximum pressure of 345 bar, and a temperature of 70°C. The system is equipped with three 35L separators, precise pressure and temperature control, and a high CO₂ flow rate of 30 kg/min to optimize efficiency. With a fully automatic CO₂ recirculation system, a high-precision PID controller, and a heat pump with COP = 6, the system ensures clean extraction, energy efficiency, and environmental sustainability.

Extraction Systems

The SFC (Supercritical Fluid Chromatography) system is used for the extraction and purification of compounds. It utilizes supercritical CO₂ to efficiently separate compounds, especially hydrophobic and chiral (optical isomer) compounds. This system is suitable for pharmaceuticals, food, cosmetics, chemicals, and many other industries.

Extraction Systems

This supercritical extraction system is specially designed for research on supercritical water and CO₂, enabling efficient extraction of natural compounds. With a CO₂ recycling system, PID temperature control, and automatic pressure regulation, it ensures precise and stable extraction. All surfaces in contact with food are made of stainless steel, preventing microbial attachment. Additionally, users can flexibly load samples and add trapping solutions such as water or alcohol to optimize performance.