Glove Box

The KK-011AS Extra from KIYON is an upgraded version of the KK-011AS, equipped with three glove ports instead of two, allowing multiple users to operate simultaneously. This design is ideal for applications that require team coordination within a sealed environment, featuring temperature control up to 200°C and flexible integration with existing antechamber systems.

Glove Box

The KIYON KK-011AS glovebox model is designed to provide a completely enclosed and tightly controlled working environment, with internal oxygen and moisture levels maintained below 1 PPM. This equipment is intended for single-user operation with two glove ports.

Glove Box

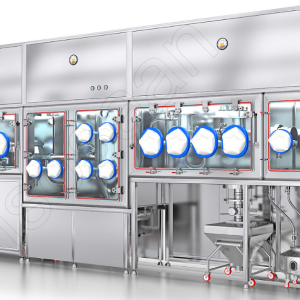

The KK-021AD model is an advanced glovebox, specially designed with eight glove ports arranged on both sides, enabling four users to operate simultaneously within a spacious work area. The product stands out with its ability to maintain a sealed environment, keeping oxygen and moisture levels below 1 ppm to ensure absolute stability and safety. Its flexible design, along with modern features such as an automatic air filtration system, a high-performance vacuum pump, and an intelligent touchscreen control panel, makes the KK-021AD an ideal choice for research, production, and processing applications involving sensitive materials that require effective team collaboration and high precision.

Glove Box

The KIYON KK-021AS glovebox is a specialized device designed to provide a sealed working environment, ideal for applications requiring strict control of oxygen (O₂) and moisture (H₂O) levels. This is an expanded version featuring a larger workspace, suitable for two operators working simultaneously.

Glove Box

The KIYON KK-PURI model is an advanced glove box designed to create a completely enclosed work environment, offering high customizability and strict environmental control. The product is ideal for applications that require a high-purity environment, such as sensitive material research, lithium battery manufacturing, and handling of special chemicals.

Isolator

This is a Negative Pressure Isolator completes a major share of manufacturing in Oral Solid Dosage Lines.

Spectroscopy

The handheld Raman spectrometer for pharmaceuticals is an advanced solution that enables rapid and accurate analysis of pharmaceuticals, from raw material inspection to identifying counterfeit or substandard drugs. With a compact design and lightweight build of just 590g, the device is easy to carry and use on-site. Cutting-edge Raman scanning technology allows the identification of over 14,000 substances, supporting the analysis of solids, liquids, powders, and tablets in just a few seconds. Equipped with a 3.5” TFT display and USB-C, Wi-Fi, and Bluetooth connectivity, the spectrometer ensures high performance and continuous operation for over 12 hours, making it an ideal choice for quality control in the pharmaceutical industry.

Spectroscopy

The Serstech handheld Raman spectrometer enables fast and accurate identification of chemicals, explosives, and pharmaceuticals within seconds. With an ultra-light design (590g), a 3.5” TFT display, and the ability to store over 100,000 measurements, it ensures precise analysis anytime, anywhere. Featuring Scan Delay, fluorescence reduction, and mixture analysis, the device accurately identifies even complex samples.