Extraction Systems

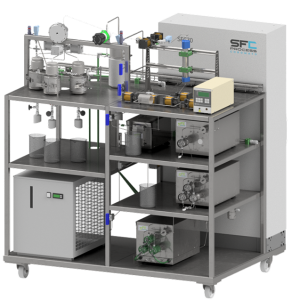

SUPERCRITICAL CO2 EXTRACTION SYSTEM IN PRODUCTION- SFE PROCESS

The supercritical CO₂ extraction system for industrial-scale production delivers high efficiency, enabling the extraction of pure compounds without altering their biological activity. With an automated design and optimized pressure and temperature, the system ensures fast, safe, and CO₂-efficient extraction. It is the ideal solution for the food, pharmaceutical, and cosmetics industries, enhancing product quality and optimizing production processes.

Extraction Systems

This supercritical CO₂ extraction system lab is designed to operate at high pressures of up to 1000 bar and temperatures of 100°C, delivering superior performance in the food, pharmaceutical, cosmetics, and scientific research industries. With a versatile capacity ranging from 100mL to 2L, the equipment flexibly meets the needs of extracting high-purity compounds. The system features an optimal CO₂ flow rate (0-100 g/min) and an efficient separation mechanism, ensuring a fast, safe, and precise extraction process. This advanced solution enhances product quality while optimizing production costs.

Extraction Systems

The SFC (Supercritical Fluid Chromatography) system is used for the extraction and purification of compounds. It utilizes supercritical CO₂ to efficiently separate compounds, especially hydrophobic and chiral (optical isomer) compounds. This system is suitable for pharmaceuticals, food, cosmetics, chemicals, and many other industries.

GansCoater® is an advanced film coating system that meets cGMP, FDA 21 CFR Part 11, CE, UL, ATEX, and ISO 9001 standards, ensuring quality, safety, and strict regulatory compliance. With the capability to handle batch sizes ranging from 50 to 300 g, the machine is equipped with an R-mini nozzle, Watson Marlow peristaltic pump, and a signature smooth, perforated coating pan. Its compact design, easy operation, and tool-free process unit changeover optimize coating speed, film uniformity, and minimize material loss.

Tablet & Capsule Inspection

The DT 1000+ Tablet Disintegration Tester is designed with two independently operating baskets, enabling simultaneous testing of two different sample types to optimize efficiency and time. The device incorporates advanced features such as precise temperature sensors, automatic disintegration time recording for each tablet, and the ability to store up to 20 methods, ensuring accuracy and effectiveness in quality control processes.

Dissolution Tester

The DS 14000 (Basic) SMART dissolution tester is the perfect solution for pharmaceutical laboratories, designed to assess tablet dissolution in compliance with international standards such as USP, BP, IP, and JP. Featuring a 12+2 vessel configuration and an automatic tablet dispenser, the device enables comparative studies while ensuring precise and efficient testing processes. It is an ideal choice for quality control and product development in the pharmaceutical industry.

Dissolution Tester

The DS 8000 (Basic) SMART dissolution tester is a modern device that complies with international standards such as USP, BP, IP, and EP, providing high-precision drug dissolution analysis. The equipment is equipped with a 6+2 configuration water bath, an automatic tablet dispenser, and a digital temperature sensor to ensure strict control over the testing process. With auto-recovery capabilities and intelligent software, this is an ideal solution for pharmaceutical laboratories.

Dissolution Tester

TABLET DISSOLUTION TESTER DS 8000+ WITH PISTON PUMP – LABINDIA

The Labindia DS 8000+ with Piston Pump is a semi-automatic dissolution testing solution designed for precise and efficient drug dissolution testing. Its mono shaft design allows easy switching between apparatus I and II, eliminating routine height validation checks as per pharmacopoeia requirements. The PP 08 Piston Pump, equipped with a chemically inert ceramic rotor, ensures compatibility with various media, including surfactants, and resolves absorption issues.