Dissolution Tester

Mahir company specializes in supplying accessories for dissolution equipment.

The agar preparation ProfiClaves PC10/20 are fully automated Agar/Media Sterilizers, capable of processing 9/16 liters in just 1 - 1.5 hours. An intuitive touchscreen interface provides access to 20 programs, offering single or double heating cycles, autoclave or water bath mode, and convenient time-delay functions. The system features a built-in pressure pump to prevent flash boiling, a powerful magnetic stirrer, a sterile filter for pressurization, and SD card data logging. Its tool-free design allows easy vessel access, while automatic pressure correction optimizes de-aeration. When combined with Biotool’s PetriSwiss dish filling systems, the PC10/20 offers a complete and efficient solution for media preparation.

The ProfiClave PCX sets a new standard for automated sterile culture agar preparation. Connected to any BioTool dish filler it provides a reproducible filling and stacking system.

Microbial Monitoring

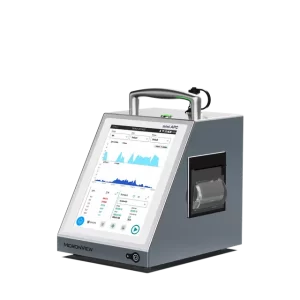

Mini APC is a specialized airborne particle counter used to monitor particle contamination levels in environments such as cleanrooms, pharmaceutical manufacturing, microelectronics, and other industries that require strict air quality control. The device supports data analysis according to international standards such as ISO, EU GMP, and Fed Std, helping to ensure air cleanliness in compliance with rigorous regulations.

Microbial Monitoring

The Remote APC Series is an advanced airborne particle monitoring solution that offers high accuracy, flexible integration, and real-time monitoring capabilities. With various options available, this product is ideal for industries that require strict air quality control, such as healthcare, pharmaceuticals, electronics manufacturing, and scientific research.

Microbial Monitoring

The APC&BAS Dual Mode Robot is an advanced automation system designed for cleanrooms, which monitors the environment by integrating an Airborne Particle Counter and a Bioaerosol Sampler. This robot utilizes intelligent navigation technology to perform precise sampling, minimizing human involvement and optimizing monitoring efficiency.

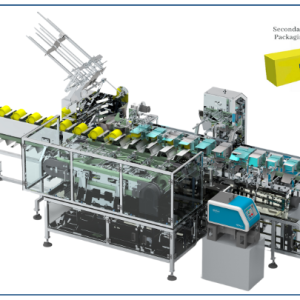

Filling & Packaging Machine

The fully automatic cartoning machine ACM-100 from Infinity Solutions is an advanced device designed to fully automate the process of packing products into cartons. With its ability to continuously erect, insert products, and seal cartons, the ACM-100 ensures high efficiency and absolute precision. The machine can handle various types of products and cartons, making it ideal for large-scale industrial production, boosting productivity, and reducing labor costs.

Tablet & Capsule Inspection

The DEFOIL automatic blister removal machine is an advanced solution in the pharmaceutical industry, designed to efficiently recover tablets and capsules from rejected blister packs. With its ability to quickly adapt to different blister sizes, the machine ensures a smooth production transition. Its advanced cleaning system maintains the highest standards of hygiene, ensuring both product integrity and sterility. Precise pressure control guarantees that the recovered products are not damaged, making them ready to re-enter the production cycle at the highest quality.