The Raman-SEM microscope is the world’s first fully integrated system combining Raman spectroscopy and Scanning Electron Microscopy (SEM) in a single instrument. With its novel correlative microscopy approach, RISE merges the ultrastructural surface analysis capability of SEM with molecular compound information from confocal Raman imaging. The system enables seamless switching between Raman and SEM measurements, supported by a user-friendly software interface for intuitive control. The RISE microscope not only maintains the full performance of both techniques but also provides precise correlation between the measurement results.

For the user with challenging experimental requirements, the alpha300 RS facilitates confocal Raman imaging in combination with Scanning Near-field Optical Microscopy for optical imaging with resolution beyond the diffraction limit. It combines all features of the alpha300 S and alpha300 R and many AFM operation modes. Furthermore the combined Raman-SNOM microscope is ideally suited for high-resolution Raman imaging techniques such as nearfield-Raman imaging.

Milling and Mixing

SuperGran® is a cutting-edge wet granulation technology designed to overcome challenges in traditional granulators, such as non-linear scalability, long processing times, inconsistent granulation, and high energy consumption. Equipped with 1 to 4 uniquely designed impeller blades connected to a rotary shaft and scraper, it creates a uniform shear environment for rapid, consistent, and scalable granulation. As a high-speed granulator, SuperGran® is widely used in the pharmaceutical, chemical, food, nutraceutical, and EV battery industries.

Spectrophotometers

The SCHMIDT + HAENSCH electronic reflectance-meter for automatic color grading of crystalline sugar according to recommendations of ICUMSA, method GS2-11 (1994) and GS2-13 (1994). With this instrument the reflectance factors at 495 nm and 620 nm are measured and the ratio is indicated in terms of color type numbers. The consistent use of high integrated circuits, very little heating, and easily detachable lighting unit ensure that the Saccharoflex 2020 is a reliable and easily maintainable measurement system which corresponds to the high SCHMIDT + HAENSCH quality standard. Ceramic calibration standards are also available.

Refractometer

Our VariRef refractometer ensures high precision throughout the product lifecycle, supporting multi-point calibration for an extended measurement range. With rapid temperature control and an adjustable sample compartment, it measures both liquid and solid samples. All VariFamily devices can connect to web browsers on any device. Additionally, a pharma-ready module compliant with 21 CFR Part 11 is available, including full documentation and options.

Table Press

Roller compactor is an advanced device that integrates three functions: compression, milling, and granulation, providing an optimal solution for the production process without the need for water or solvents. This simplifies the granulation process by eliminating the drying step, ensuring high stability of the granules and excellent flowability, making them ideal for tablet compression or capsule filling. By enhancing the density, specific gravity, and quality of granules, the machine also offers additional features such as a vibration sifter for re-granulating undersized granules and an automatic suction conveyor to save labor costs. It is an ideal choice for the pharmaceutical, food, and chemical industries.

This is a Negative Pressure Isolator that plays a pivotal role in almost all Pharmaceutical Industries like API Manufacturing, Formulations, OSD etc. The Isolator can carry out Sampling & Dispensing Activities.

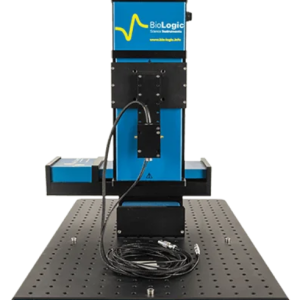

A modular, state-of-the-art instrument allowing users to exploit 9 local electrochemistry techniques.